Decks 101: How to Frame a Deck

Decks 101: How to Frame a Deck

Decks are so much more than just some boards of lumber nailed together in your backyard; decks are a gathering space. The ultimate DIY construction project, decks are the perfect area for outdoor entertaining and relaxing in style year-round. As your family and friend group grows and expands over time, be sure to make space to celebrate and connect together. The trend of outdoor living spaces is rising everyday with families looking for the best way to invest in their property and create the space they've always wanted for their home.

You've daydreamed it. You've talked about it. Even recruited some friends and family to help with the heavy lifting when the time comes. Now it's time to research, plan out, and truly build your deck.

Why is deck framing important?

Deck framing is incredibly important as it determines the structural integrity and strength of your outdoor living area. Making sure that you build a safe and code compliant deck assures you won't have problems with building inspectors or the group of friends you invited over for the BBQ.

What's the best deck framing material?

Pressure-treated lumber such as yellow pine, hem-fir are extremely popular framing material options as they are inexpensive and readily available. Cedar and Redwood are also used often as they are naturally decay-resistant. For the strongest and longest lasting substructure, however, the deck industry is moving into metal framing options such as the Fortress Evolution Steel Framing systems. Metal framing is durable, consistent and features unparalleled strength compared to lumber options.

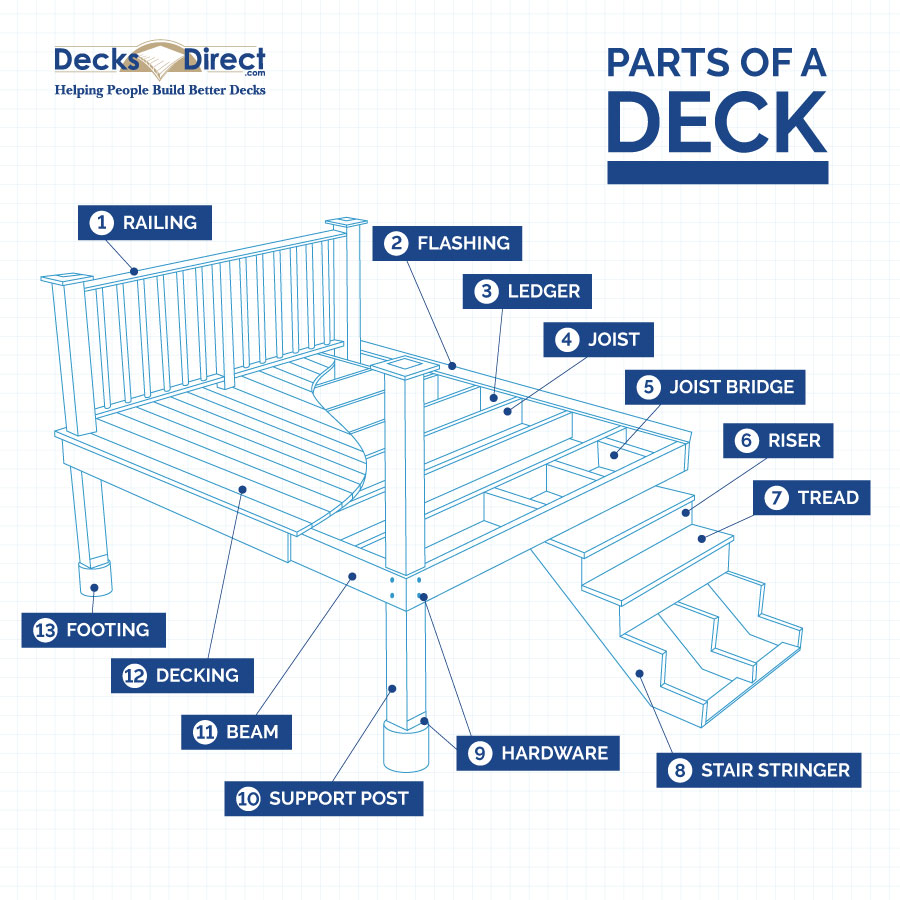

1. What's deck flashing?

Deck flashing is a corrosion-resistant and waterproof material that is attached to your ledger board. This material will prevent any water from entering the wall of your home through any openings you create while attaching the ledger board. Generally flashing material is made from stainless steel, copper, or vinyl material and will be available in roll form or in rigid sheets.

2. What's a deck ledger?

A Ledger Board is a lumber or framing component that is attached to the house by being bolted through to the house's framing. From the installed ledger board, joists will be attached perpendicularly with brackets to create the width of the deck.

3. What deck hardware do I need?

Structural hardware such as joist hangers, post to beam brackets, post base brackets, lag bolts, and connectors are typically going to be needed to attach the deck frame together. Simpson Strong-Tie is a contractor-favorite brand for structural building components.

4. What's a deck joist?

Joists are structural elements that make up the entire framework of the deck. Joists are attached to the installed ledger board using a joist hanger, or hanger bracket, and run the entire distance of the deck out from the house.

How far apart should deck joists be spaced?

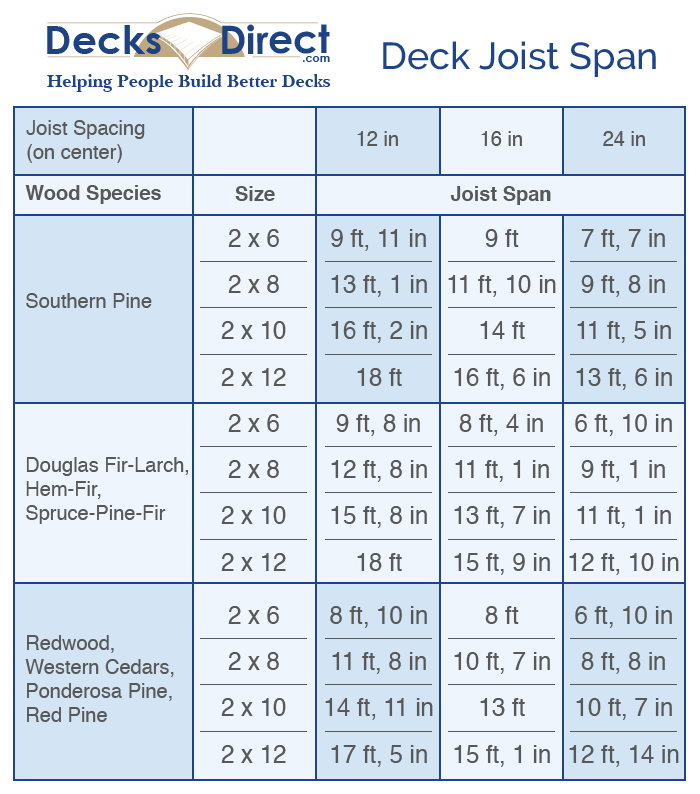

Deck joists are typically spaced either every 12 inches or 16 inches on center. The maximum joist spacing you can use will depend on the size and allowable span of your joists.

What's the maximum span for a deck joist?

Deck joists have a different maximum span length depending upon the size, spacing, and framing material that you're creating your deck with. Here's a helpful chart covering the most popular wood framing species and their maximum allowed spans:

5. What's deck joist bridging?

Bridging, also known as blocking, is a structural component installed between each joist for increased support to prevent any movement or bouncing once installation is finished. Blocking is also installed along the perimeter rim joists to ensure a solid deck railing installation. Scrap pieces of the framing lumber, or specific metal components, may be used for blocking.

How do I install blocking on deck frame?

Blocking, or bridging, is often installed between joists at mid-span and along the perimeter rim joists. Typically blocking is installed in a alternating, zig-zag, or Herringbone pattern for increased strength and is mounted flush with the top of the deck frame.

6. What's decking?

Decking is the actual boards of material on the top-facing surface of the deck which you will walk and sit upon. Deck boards will be attached to the deck frame by connecting directly to the joist by face-fastening via Deck Screws, in a concealed face-fastening method via a Pro Plug System or in a nearly invisible manner with a Hidden Deck Fastener system. Popular decking material includes natural or pressure-treated lumber, composite decking such as Trex, TimberTech, and Deckorators, or innovative aluminum material.

7. What's deck railing?

Deck railing is the system or setup installed along the perimeter of the deck and along the outside of staircases to prevent family, friends, and pets from any harmful falls. Safety aside, deck railing can also highlight and accentuate the architectural details of your home that you like the most. Choose between stately columns, modern stainless steel cable or transparent glass to complete your home's aesthetic.

What's the best deck railing material?

Deck railings are made from many different materials including aluminum, composite, glass, stainless steel cable, vinyl, and wood. Choosing the best railing material means considering the look, style, and purpose your deck serves. To dive deeper into the railing styles available for your outdoor space, browse through our Metal Railing, Cable Railing, Glass Railing and Composite Railing pages to find the style that best suits your space.

8. What's a deck footing?

Deck footings are bases for the support posts and keep them in place throughout the years. Footings generally consist of a concrete base or pillar installed under ground below the frost line to which a support post is inserted or attached to via a bracket. Deck footings must be installed below the frost line in a region to prevent swaying and movement throughout the freeze and thaw weather cycles of the year.

Why are deck footings important?

Deck footings help to spread the weight load of the deck from the top of the support posts to a more concentrated, solid setting in the soil. The more deck footings your deck frame has, the more evenly distributed your weight load will be.

How deep do footings for a deck need to be?

Footings for deck frames must be driven down into the ground below the frost line to avoid any movement or shifting throughout the seasonal changes. Be sure to check your local building codes before building. Check your local frost depth here.

How do I make a deck footing?

Use a posthole digger to create holes deep enough down to extend below the frost line of your region. Create a frame for your footing using either scrap lumber or a cardboard tube, and pour the appropriate amount of wet concrete for your project into the mold. There should be at least 12 inches of solid concrete surrounding and completing your deck footing. Let harden for 24 hours. You may pre-attach a galvanized post base to the support post before pouring concrete or attach the support post to the footing after curing.

9. What's a support post for decks?

Deck support posts are the vertical component attached to or mounted within the deck footing and sustain the weight load of the deck. Deck support posts are generally made from wooden 4"x 4" posts, however, deck construction is now recommending installing 6" x 6" support posts to prevent bowing over time. Support posts are generally attached to the footing using a structural code compliant Post Base Kit and concrete screws such as the Caliburn XL Concrete Screws or the Concrete and Masonry Screw by Simpson Strong-Tie.

How far apart should footings and support posts be for a deck?

Deck support posts should be no further than 8' apart, though for a sturdier frame a shorter distance between footings can be used. The maximum spacing is determined by your joist size and span.

10. What's a deck beam?

A Deck Beam, or Support Beam, is a sturdy structural piece of lumber or metal that spans the length of the deck along or parallel with the house. A deck beam will support the entire weight of all the floor joists and transfer the weight load onto the support posts and ultimately the deck footings below ground.

11. What's a stair stringer?

A stair stringer refers to the support frame for the stairs to which the risers and treads of the stairs are attached. Typically, stringers are cut out from framing lumber, such as 2" x 8" or 2" x 10", specifically to the staircase angle and specifications. Two to three stringer boards are installed to the framing of the deck and on both the treads and risers of the stairs are attached to them.

What do I need to build stairs for a deck?

Stairs are made up of three essential parts: stringers, treads, and risers. Stringers are sloped boards that are attached on both sides of the staircase to provide support and carry the weight load. Treads are the top surface of the steps which will be stepped upon, while the risers are the vertical sections at the top of each step.

How do I frame stairs for a deck?

First, calculate the rise and run of your staircase. Measure, mark, and cut your stringer boards to your specific measurements. Attach the stringer boards to your deck frame, stringers are usually attached to the rim joist or to the framing under the deck. With your stringers mounted, install tread and riser boards directly to the stringer.

How do I find the rise and run of my deck stairs?

Lay a board flat on the top of the deck, extend it out from the edge until over the location of the last step and measure down to the ground. That will be the total rise

of your stairs. Divide that measurement by 7 inches, the most common rise per step, to find the approximate number of steps in your staircase. If your amount isn't a whole number, round either up or down to the closest whole number. Divide your total riseby your number of stairs to find the actual rise of each step. Then multiply the number of stairs by 10 inches, the most common run per step, to find the total run of your stairs.

Rise and Run Example:

Example: Total rise

= 70 in

70 in ÷ 7 in = 10 steps

10 x 10 in = 100 in = Total run

of stairs

Rise/Run = 7 in /10 in

12. What are stair treads?

A stair tread is the horizontal, flat surface of a step which people and pets step upon. Generally, stair treads measure around 10 inches deep to provide enough room for guests to comfortably fit their foot on the piece. Building a stair tread that is much larger than 10 inches can create an awkward step, while building a stair tread much smaller than 10 inches can make guests feel uneasy and may create slips and falls on the staircase.

13. What's a stair riser?

A stair riser is the vertical, up-right surface of a step that provides backing for the stair tread and prevents feet or other items from falling through the stairs. Generally, stair risers measure around 7 inches high to provide a step size that is comfortable for the user. Building a stair riser much higher than 7 inches can make it difficult for friends and family to get up and down the stairs easily, while a stair riser much shorter than 7 inches can be liable to catch toes on the edge.

14. What are stair skirtboards?

A skirt board is a piece of lumber or composite material which is used as a trim or cover piece for the structural section of the stairs. A skirt board is installed to the finished wall or stringer to help complete the look of the staircase and provide additional weight load support for less movement. Skirtboards will be cut to match the pitch, rise and run of stairs and will help complete the look of the finished staircase.

Are you sure you would like to remove this item from the shopping cart?

This item is a part of the approved quote. Removing it will remove all quote items from the cart.